User:Gfc

Bio

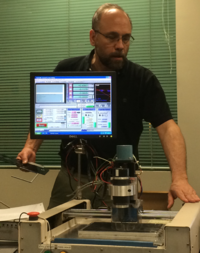

My background is in aviation, computers, technology, publishing, facilities, and generally making stuff.

Favorite Maker Tech

I enjoy working with CNC routers and mills, laser cutters, wood shop tools, and a variety of others

Working to Learn

I'd like to learn more about sewing and analog electronics.

Ask Me About

Anything at all

Contact

Contact me on Slack. My office is Iribe 1214 just outside Sandbox. gfc@umd.edu

My vCard may be found at https://vcard.link/card/DtX8.vcf. or https://drive.google.com/file/d/1hDQO4FA1fhW14RVTGElPFX181iETHs0o

Statistics

Numbers returned by these variables normally contain separators (commas, dots or spaces, depending on the local language) but can return raw numbers with the ":R" flag (for example, {{NUMBEROFPAGES}}404 and {{NUMBEROFPAGES:R}}404).

Use "|R" for magic words that require a parameter like PAGESINCATEGORY (for example {{PAGESINCATEGORY:Help}} and {{PAGESINCATEGORY:Help|R}}, or {{PAGESINCATEGORY:Help|subcats}} and {{PAGESINCATEGORY:Help|subcats|R}}).

| Variable | Output | Description |

|---|---|---|

{{NUMBEROFPAGES}}

|

404 | Number of wiki pages. |

{{NUMBEROFARTICLES}}

|

54 | Number of pages that qualify as articles. |

{{NUMBEROFFILES}}

|

201 | Number of uploaded files. |

{{NUMBEROFEDITS}}

|

2,888 | Number of wiki edits. |

{{NUMBEROFUSERS}}

|

2,589 | Number of registered users. |

{{NUMBEROFADMINS}}

|

8 | Number of users in the sysop group |

{{NUMBEROFACTIVEUSERS}}

|

1 | Number of active users, based on the criteria used in Special:Statistics. |

TEST

Useful Links

Send Cut Send

https://sendcutsend.com/blog/designing-for-laser-cutting-in-illustrator/

Stanford Product Realization Lab:

https://productrealization.stanford.edu/processes/laser-cutting

AI tutorial: https://docs.google.com/presentation/d/1z087MwHaTHqJUPTVTnqvE-XLY0c031lp_Oz9ENlezTY/edit#slide=id.g5d3d426aba_0_0

Laser tutorial: https://docs.google.com/presentation/d/1yVlppWgw7UhS05BuYInmd-EBGjT4-OQTU4XLuBCQz7o/edit#slide=id.g5394391f19_0_305

others

AI / Laser setup guide: https://www.freefall-laser.com/file-setup

List of links https://www.mrerdreich.com/resources

https://razorlab.online/prepare-laser-cutting-vector-files-using-adobe/

Management Organization

Sandbox is managed by small staff and a larger team of volunteer Managers and Advisors.

Staff, Volunteer Managers, and Advisers

- Staff The current Sandbox staff is made up of:

- One full-time faculty assistant.

- Several part-time student employees.

- Volunteer Managers are the core of the Sandbox workforce. They assist makerspace visitors with a wide-range of functions. For more information about the roles and responsibilities of managers, click here

- Advisers contribute to the space by leading workshops. For more information about the roles and responsibilities of Advisors, click here

Current Roster

yes

| Wiki User Page |

|---|

| Role | First Name | Last Name | Wiki User Page (& Recent Contributions) |

|---|

ExternalData without Table

Use Display External Table

| Name | Role | BestEmail | WikiUsername

|

|---|

Tips for 3D Printer Bed Adhesion Problems [draft]

What is one of the most frustrating things that can happen when you’re 3D printing? A failed print due to bed adhesion issues. We've got six easy tricks to help your 3D prints to stick to your build plate.

1. Clean the Bed

If you’re having bed adhesion issues, the first action you should take is cleaning your build plate with 91% or higher isopropyl alcohol. If your bed has old filament, dust, oil, adhesive residue, or debris, this can create bed adhesion issues. When there is a layer of debris on the bed your first layers aren’t directly on the build plate, they are adhering to the dust, not the plate. Later in the print, this will cause it to move and sometimes comes entirely off of the bed.

2. Level the Bed

Any small movement or bump to your printer can move the bed causing it to be uneven. We recommend manually re-leveling the bed, but if you have a 3D print with auto level, you can try this as well. After auto leveling, if your prints still aren’t sticking, try to manually level the bed.

Thingiverse user Chep has a Bed Level STL that can help test your bed level.

3. Adjust Bed Temperature

If your bed is not set at the proper temperature, this will cause poor bed adhesion. Your bed temp will depend on the type of filament you are printing with. Begin at the lowest recommended temperature and increase by 5° as needed until you reach the max temperature.

See below for recommended Inland Filament Bed temps:

i. Inland PLA: 55°C - 80°C

ii. Inland PLA+: 55°C - 80°C

iii. Inland ABS: 80°C - 110°C

iv. Inland PETG : 60°C - 80°C

v. Inland TPU: 25°C - 60°C

vi. Inland PETG+: 80°C - 100°C

vii. Inland Tough PLA: 60°C - 80°C

viii. Inland Silk: 60°C - 80°C

4. Adjust Printing Speed

The next setting you can check is the printing speed. If your first layer is printed too quickly, the filament won’t lay flat on the bed and your print will begin to lift. We recommend printing the first layer at 25-50mm/s and the rest of the print 60-90mm/s. You can adjust the printing speed in your Slicer Settings.

image.png 5. Adjust Z-offset

If you're still having issues, try adjusting the Z-offset. The Z-offset refers to the distance between the nozzle and the bed. The Z-offset can be adjusted in the 3D printer display menu. Lowering the Z-offset to -0.05mm will bring the nozzle 0.05mm closer to the bed. Increasing the Z-offset will lift the nozzle away from the bed. This should be tested in small increments to prevent overcorrecting.

image.png 6. Try Using Brims and Rafts

When printing small, delicate pieces that do not have a large surface area to stick to the bed, you can try using a brim or raft to assist with bed adhesion.

Brim

A Brim adds a single, flat layer around your model to prevent lifting and curling. It attaches to the first layer of your model.

image.png image.png Raft

A Raft adds a layer of filament before the rest of your print. This ensures the base of your print is flat and creates a smooth, even surface for the rest of your print to build on.

image.png image.png We used a Brim to combat curling edges when printing a Wand Holder in our 3D Print of the Month article.

image.png

To use this widget on your site, install MediaWiki Widgets extension and copy the full source code of this page to your wiki as page User:Gfc.