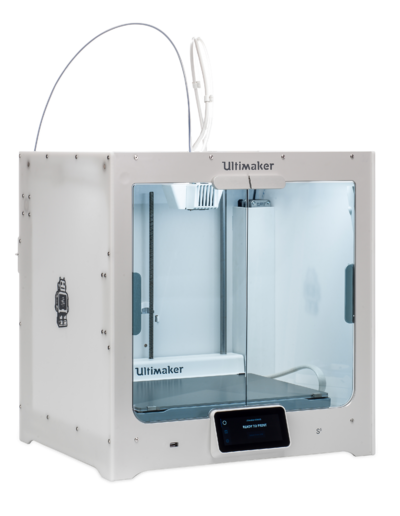

Ultimaker S5

Overview

The Ultimaker S5 is a high-end FDM (fused deposition modeling) 3D printer with dual extruders.

Fusion Deposition Modeling works by placing layers of melted material in a certain path over and over. Soon after the material is placed down, it hardens, allowing the next layer to be placed and stick on top. The path is determined by slicing an object and splitting it up into predetermined sized layers based on a setting in the editing software.

The Ultimaker's base software for creating images to be printed is Cura.

As we only have one printer, the Ultimaker is run in a first-come-first-serve basis. This means that there is no queue to get in line for having your print started. The only way to ensure that you get your print done is to be at the printer when another print finishes and start your print then. The best we can do to help you if you talk to one of the managers is if they know how to work the printer they can start your print at the end of the current one if they would still be present. This is not a guarantee. Managers reserve the right to restart or cancel prints if they look misconfigured (like forgetting support) or is failing. If a print is failing because it needs support and wasn't set properly, we will cancel it and not be able to restart it because the ultimaker needs an updated Gcode file which we cannot create without knowing the specifics of your print.

Running a print

These are the very simple steps to be able to print on the Ultimaker after completing the training on elms.

- Having an idea for a print

- Using Cura to create a gcode file out of an STL or other applicable file (See Cura flow for more information)

- Make sure if you need support you used it!

- After saving the gcode to a USB, plug in USB into the Ultimaker

- Change out the material as needed

- Using the touchscreen menu on the Ultimaker go to Print and find your print

- Make sure you have enough material left in the current spool to finish your print

- Click on your print to start it

- Hang around the sandbox at least until the first layer is done to make sure your print doesn't fail (Most of prints fail within the first layer)

- If your print fails then take it off and reprint it. If this continues to happen then ask a manager for help or try another print (Please don't waste materials failing the same print over and over)

- Come back whenever your print is done and find it in the Prototype Room and enjoy!

About Cura

- Cura can be found for free on Ultimaker's website: Cura Download

- More Cura Help

- Cura allows 3D file formats: 3MF, OBJ, STL or 2D file formats: bmp, gif, jpg, png.

- You can download Cura and prepare a print on you own computer and load it onto a flash drive for the Ultimaker

- Possible ways of getting objects to print:

- Finding and downloaded STL files from Thingiverse

- Create your own CAD files using a program like Solidworks, Siemens NX, Autodesk, or anything that will create the accepted file formats.

Choosing a Material

Each material that can be printed with have certain characteristics that allow them to be more desired than others in certain situations. Examples of qualities would be strength against breaking, temperature resistance, quality, ease, flexibility, and many more.

The Ultimaker S5 nozzle can reach temperatures up to 280 degrees Celsius and the heated bed can reach temperatures up to 140 degrees Celsius. Materials must have a melting point under 280 degrees Celsius.

For a list of Ultimaker approved materials you can visit their website

| Material Type | Advantages | Disadvantages |

|---|---|---|

| PLA (Polyactic Acid) |

|

|

| ABS (Acrylonitrile Butadiene Styrene) |

|

|

| Nylon (Polyamide) |

|

|

| PETG (Polyethylene Terephthalate, Glycol Modified) |

|

|

| TPU (Flexible) |

|

|

Manuals

For more general information you can visit their learn page